Racking – a towering force in your warehouse

A perfectly planned racking system serves as the backbone of your warehouse. As a full-range supplier, we have the perfect racking solution for you – from static or dynamic racking systems to complex, automated storage systems.

High-capacity, well coordinated solutions for your storage system

Expertise in the development of future-proof racking systems is borne from experience. For 60 years, Jungheinrich has been serving customers with its in-house developments, tailored solutions and setting the highest quality levels. This has produced a wide range of storage solutions for pallets, containers, trays, boxes and long goods. We thus ensure that all goods are well stored and easily accessible. The main benefit of racking systems is that they greatly increase your storage capacity. As a leading full-range supplier, we have set ourselves the target of providing you with the perfect storage solution for your needs. This may take the form of anything from static or dynamic racking systems to sophisticated, complex and fully automated storage systems – whatever you and your customers need to ensure long-term business success.

Efficient, safe, expandable: The benefits of future-proof storage solutions

Your warehouse requires a solid foundation to ensure its continued growth. By tailoring the racking system to suit your exact requirements, we can optimise the efficiency of the entire material flow. This includes, for example, faster throughput thanks to integration within the Jungheinrich Warehouse Management System.

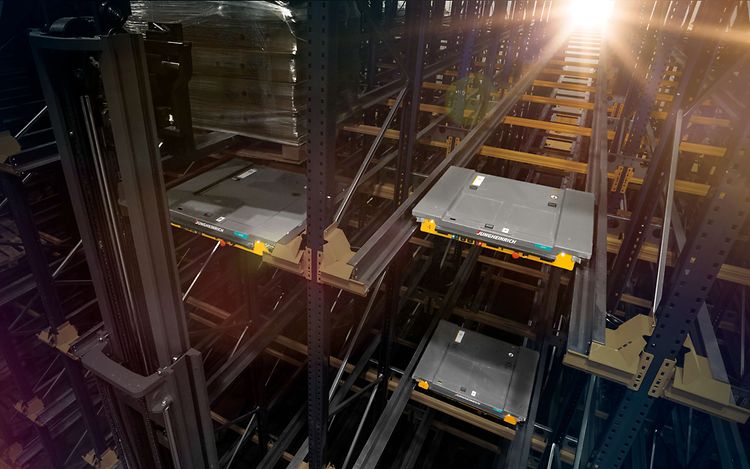

Our solutions also impress with their sophisticated technology, as demonstrated by the perfect interplay of our multi-depth storage system. It comprises of a compact channel storage system and an autonomous shuttle, known as an Under Pallet Carrier (UPC). Both components feature optional safety systems to provide optimum protection for users and machines: In the case of the UPC this takes the form of an integrated personal protection system (PPS). We also provide a stationary personnel protection system directly on the racking. The functional principle is very simple: At the front of the racking, an "intelligent" light barrier locates individual sections near ground level and ensures that the multi-depth storage system is stopped automatically in the case of danger.

Mobile pallet racks serve as a further example of optimised storage equipment. These electronically movable racks are doubly beneficial, in that they can save you both time and space when integrated in the WMS. The reason for this is that only one aisle is opened in any block at any given time, thereby increasing the amount of space that is available for racking (by up to 90 percent when compared to conventional racks for palletised goods). In addition, the use of mobile racking in combination with reach trucks can greatly increase your throughput performance. Whatever you opt for, our racking systems work in perfect harmony with our industrial trucks to optimise both your warehouse processes and your throughput.

Enhanced efficiency with warehouse storage solutions from a single source

We can tailor your partially or fully automated racking system to perfectly suit your needs and provide a comprehensive storage solution that includes a suitable warehouse management system – in the form of our Jungheinrich WMS. You will therefore have the perfect equipment for storing pallets, containers and trays as well as boxes or long goods. In addition, you benefit from a complete system solution with holistic warehouse planning in which the racking and industrial truck work "hand-in-hand" as a perfectly coordinated automatic system.

Our specialists will be happy to work with you to identify the most efficient storage system for your needs. We devote ourselves to your individual requirements, from the initial analysis and optimisation of your existing system to the creation of the perfect new system and subsequent implementation and successful handover. After all, we can only help you to achieve a competitive edge by delivering an automatic system that is perfectly in tune with your business processes. As a general contractor and system supplier, we can ensure that all systems are well coordinated and operate in perfect harmony. We do this based on the extensive experience and expertise we have gained through planning, configuring, processing and commissioning many thousands of warehouse across the globe.